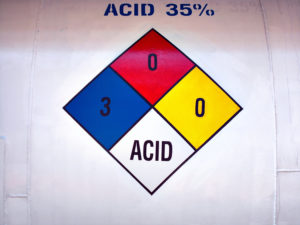

Acid is one of the most corrosive and dangerous materials chemical processing workers handle — and sulfuric acid is one of the most common agents within this group. In fact, global sulfuric acid production stands at approximately 180 million tons per year. Sulfuric acid is a clear liquid solution, soluble in water with no smell that packs a punch. Known as the “king of chemicals” due to its wide array of uses, sulfuric acid is common in operations such as chemical processing, mineral processing, petroleum refining, water treatment, and more.

If you utilize sulfuric acid in chemical or manufacturing processes at your plant, it’s incredibly important to store and handle the acid properly. This includes careful storage tank design, use, and upkeep. When determining the best fabrication options for your acid storage tanks, consider the following:

- Materials of construction — Most tanks holding sulfuric acid are made of carbon steel or stainless steel due to their abilities to resist the acid’s corrosive nature. Other factors that play a role in material selection include tank size, costs, desired acid quality, acid concentration, and storage temperature. To ensure you’re opting for the best — and safest — materials of construction, partner with a tank fabricator who understands which materials can best withstand highly corrosive acidic properties.

Ventilation systems — Ensuring proper ventilation systems is another crucial factor in tank design and safety. Tank ventilation not only allows the tanks to breath but also mitigates “harmful and potentially dangerous gases” from accumulating in the tanks. Ventilation begins with expert design but also requires employee inspection and upkeep such as looking for signs of damage or clearing debris that could block vents.

Ventilation systems — Ensuring proper ventilation systems is another crucial factor in tank design and safety. Tank ventilation not only allows the tanks to breath but also mitigates “harmful and potentially dangerous gases” from accumulating in the tanks. Ventilation begins with expert design but also requires employee inspection and upkeep such as looking for signs of damage or clearing debris that could block vents.- Secondary containment liners — Acid containment is of the utmost importance. Erosion is “especially common” in sulfuric acid storage tanks. Secondary containment liners help seal and protect the metal, creating an additional barrier to fight back against such highly abrasive materials. This can help reduce wear, improve tank integrity, and safeguard your facility from detrimental tank failures.

Storing and handling acid or other harsh chemicals can present many dangers to your facility, your employees, and the environment. Tank failures can go beyond tank damage and maintenance costs; they can result catastrophes such as fires and explosions. Acid storage tank fabrication requires special consideration and, due to safety concerns, leaves little to no room for error. Choosing an experienced and knowledgeable tank fabricator is incredibly important.